What do you need to remember when installing the door?|We are building a house

Wing + frame = door

The wing consists of a frame, running around the perimeter, and segments with a plate or panel structure.Inner space is often filled with material with good insulation or acoustic properties, e.g..polystyrene, polyurethane foam or polyamide insert.Plate wings have, on both sides of the rectangular frame, rigid panes made of wood -like materials or e.g..made of aluminum, finished with veneer or foil veneer and decorative slats with a cutter.Popular wings - a surface divided into smaller segments (panels), filled with decorative elements - wood, glass, etc..

Wooden versions are made of solid or layer wood.Pine, beech, oak or exotic is most often used.Wings made of wood -based panels are made of chipboard or several varieties of fiberboard - ordinary, i.e. hard MDF, and HDF, i.e. very hard.They are finished with either wooden veneer (more expensive variants), or laminate veneer (cheaper), possibly covering paint (cheapest).When using glass doors, it is better to choose a tempered or with foil laminated for safety.The toughened panes are impact resistant, and if they still break down, they fall into blurred pieces.The glass connected to a special foil may break, but it will not fall apart.

The edges of the wing are equipped with synthetic rubber seals or EPDM.If they are chamber gaskets, sometimes it is better to replace them with flat, which are less elastic and do not cause stress in the castle.You can buy them in construction hypermarkets.Wings with a width not exceeding 90 cm are usually attached to two hinges, but wider on three.Finished wooden internal wing with a frame and mounting accessories cost from about PLN 300.

Frame.The wing and frame must perfectly match technical and aesthetic terms, which is why the frame is most often made of the same material as the wing, i.e. from wood or its derivatives.The exception is all of the glass wings - they do not have glass frames, but made of wood or wood -based plate.Such frames are sold as standard with a clutch sheet and a seal.

Skrzydło bezprzylgowowe z podwyższoną ościeżnicą optycznie podwyższa wnętrze. (fot. Porta)Preparation of the jam

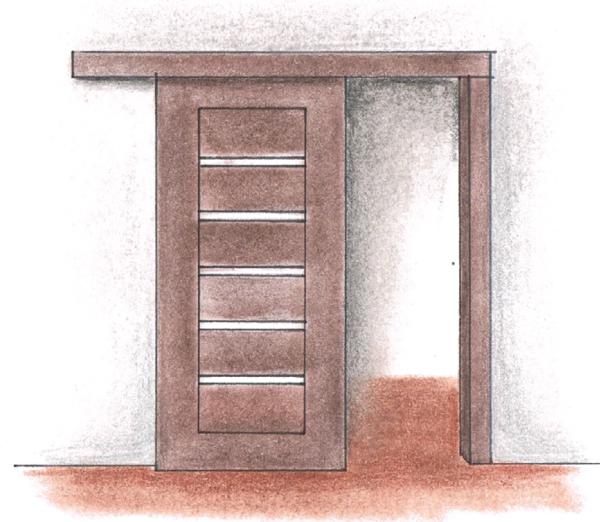

Preparation of the hole in the wall (i.e. the frame) takes place in the stance phase of the raw structure, at the stage of erecting internal walls.The subsequent correct assembly and trouble -free use of the door for years depend on whether the partition is perfectly vertical and the dimensions of the hole precisely made.Correct prepared frames avoid forging or dominating the walls in the finishing phase of the construction of the house, in which the frame and door wings are embedded.

Errors are particularly undesirable when setting the height of door openings - due to the fact that they are crowned with reinforced concrete lintels.Before buying a frame and a wing.And also measure the wall thickness and choose the type of frame adequate to it.The so-called constant always fits the partitions with a standard thickness and is 6-8 cm, while the frame with the adjustment function is suitable for walls with unusual thickness and wings 60-110 cm wide.

Nowoczesne drzwi w stylu loftowym mogą być wyposażone np. w hartowane szyby transparentne lub malowane na biało lub czarno. (fot. Voster)Installation of the frame and wing

The door should be inserted by the manufacturer's or seller's employees, especially if it is a condition for granting a guarantee.You can also embed the door frame yourself (this is not a complicated activity), using - levels, wedges, hammer, screwdriver, assembly stories, mounting foam, silicone, wood glue, etc..Castles, fittings and all accessories necessary to put on and operate doors. Manufacturers attach to the frames and wings.Only door handles are usually bought separately, most often ensuring that they are equal in the whole house.

So that the door frame and door leafs do not be parked, their installation is carried out after all wet works, i.e. in rooms with finished walls (plastered and painted) and with ready -made floors.

The exception is a metal frame, which as more resistant to damage - than the one made of wood or wood -based panels - can be inserted at the stage of raw state, in non -leinated walls.If the door opening is properly prepared and it is not necessary to correction (leveling the surface of the hole and supplementing the cavities), then the work begins with the assembly of the frame of the frame.Then, with the help of wedges, it is set in a door hole.

The next step is to check the vertical and frame level using a level, then the use of assembly stations (estates at three heights are required).Such a frame is set with anching wall, after drilling the appropriate size of the holes, and the mounting foam.But beware!It must be applied with sensitivity, because it expands and too much of it can cause a deformation of the frame and problems with the operation of the door.

When the foam binds (it usually lasts 3-4 hours), the dismantle is dismantled and the wedges are removed.After cutting the excess hardened foam.

The penultimate activity is to attach the wing on the hinged and adjusting them in such a way that the door closes properly.The last one - screwing the door handle.

In the case of light wings, some manufacturers allow assembly only for foam, without the use of anchors.

Lilianna JampolskaFot.Opening: Classen