Krzysztof Francisszewski's Toyota BJ42 - an original in every way

06 Oct 2008:

So the machine started. The object of reconstruction is BJ42 from February 83. Many of you will say - why such a fresh car? It wasn't better than some old man from the seventies. Maybe it's better, but you have to start somewhere. I start with what is already there and the next will come. Today, from the west, I knocked down a few unnecessary things like chrome rear lamp covers, a thermometer, a magnet counter and stuff. The assumed date of completion of the works is next year's Camp Coyot. I want to bring the car to the original, i.e. cherry color and chrome rims go weck. To begin with, I made a small body shop shopping list. It will not be easy, as far as I have access to repair kits, I am interested in whole elements such as doors, bonnet, etc. Toyota in Europe can no longer help - finished production. I sent an inquiry to the states. I decided quite seriously and want to implement my plan, and the plan assumes as little putty as possible. On Wednesday I pick up the steering bracket and I want to drive it a bit. A friend, a tinsmith, looked at it today and initially undertook the reconstruction from the tinsmith's side. He was pleasantly surprised. We have an appointment in two months. As the project develops, I will inform you about everything along with photos.06 Oct 2008:

I have already ordered the front fenders in the original. You can buy fakes, but the thickness of the sheet and the quality of workmanship leaves much to be desired. I counted that sandblasting plus varnish and preparation will come out similar to new. I put my seventy on the originals and they have no comparison to the replacements. Replacements have to be made and combined. For those interested in Toyota, the following are no longer available: - front door - hood - rear door - front grill (large) - elements of the board - gear knobs and reducer - windshield frame With mechanics there should be no problems. What I can look for in replacements, but branded or produced for Toyota. E.g. Aisin07 Oct 2008:

I also have a jack with extensions. Pouch with tools is missing but already traced. Some of the items on the list above are available from Toyota USA. Tomorrow I will have prices and availability.

08 Oct 2008:

Today I went through the whole EPC. Page after page, I analysed, wrote, took notes, and made a plan. It won't be easy and I think I have to play the lottery. In the states, it turned out that it is also not colorful with parts. I found used parts but in perfect condition and I'm supposed to get prices tomorrow. Will try to order another batch of trinkets tomorrow as well. I'm also starting to collect mechanical replacements so that everything doesn't collapse at once. Brake pump, water pump and stuff. A table in Excel will allow posterity to estimate the costs of such a repair. A similar plan to mine is here: http://www.landcruiser-experiment.de/20 ...chive.html Of course, I mean fragments related to rebuilding the car, not repairing the washing machine and garage insulation

13 Oct 2008:

It won't be easy. Increasingly large stairs. With everything a problem or mega poor availability. Same with the mechanics. Of course, there are substitutes, but most wholesalers have never downloaded it. I spent a few hours looking for parts on ebay and found a few bits and pieces. For example, the front grill sheet in the original. Unfortunately, it's not cheap, but we'll see what we can do. I'm looking for originals first. Only then will the repair kits to which I have access even from my own shelf go in motion. Today I received some nice little things (all new): - Land Cruiser inscriptions on the fenders (with this beautiful tilted font) - original bonnet closures (I have some rubber ones straight from a beetle) - inscription Diesel on the front grille - 3B sticker on the engine - Diesel sticker on the fuel filler flap (there are also Japanese bushes on it) The car has already dismantled super halogens, additional rear lights, radio, inclinometer and a handful of unnecessary cables.

15 Oct 2008

The work has started in full swing. The decision was made to disassemble and make two cars at the same time. Mine and Emsie. The green vehicle was practically dismantled today. Mopar is pushing at our workshop next to Michał's car. Young also helped for an hour. Even I jumped into dungarees today. We're taking the hood off tomorrow. Mine is going to be disassembled next week. The first exchanges between cars are already included. The heap of spare parts for the original is growing: - Toyota lettering on the front grille - sticker with the reducer manual - sheet metal covers under the seats. 08 Nov 2008: [PHOTO. 1]

Time to get down to some serious work. I took some photos of the car before the renovation. Today I got in the car and took it to the house to test it a bit and write down what hurts him. This is actually my first ride apart from a few circles around the workshop streets. The box runs perfectly and quietly. 90 km/h is not a problem for it. It smells a bit when cold - there is probably a problem with the spark plug in the manifold because someone replaced it in the engine. There is a lot of work waiting for me inside. Parts gathering continues. The most difficult to get are the elements of the board and the middle panel. (no longer produced) The seats and back sofas will go to the upholsterer. Metal elements will be sandblasted and powder coated in dark gray in accordance with the original. New sides have already been ordered. Of course, only available in the US. The same goes for the zippers and handles. The speakers make a getaway just like a radio that is no longer there. It will be replaced by Blaupunkt from that era - I still have the Beetle left. As I have a second engine in stock, its general overhaul has begun. It stands on an engine stand and I started to disassemble it, of course, verifying the parts to be ordered. On the next holiday, November 11, I am going to completely dismantle it. It is such elements as the visible cover that I want to restore to new ones. Therefore, a chemical preparation for aluminum is needed, which I wrote about in another topic. The oil cooler cover and the oil pump patch look similar. Elements such as the collector will be sandblasted because they are dull anyway. You can see what the coolant was like. Rather, he still remembers the times of the People's Republic of Poland when this car drove on Polish roads. After unscrewing the fuel filter, it turned out that it was running on fuel Very nicely visible royal timing gear. This engine does not have a typical belt, so it does not need to be replaced and there is nothing to break. A great solution for HD cars. Mr. Kazio servicing this car used yellow paint to assemble the lid. I wonder what he was looking for. The head is already removed. The cylinders don't look too bad, and nobody's done a polish yet. Unfortunately, the head is cracked on the first cylinder and will go to the office as a piece of furniture11 Nov 2008 [PHOT. 2]

The engine is already dismantled to pieces. It remains to pull out the pistons and the shaft, although the inspection of the bushings has already been done. They look like someone installed them yesterday. Even the smallest scratch. The same applies to the crankshaft. Everything without a cut in nominal terms. Tomorrow I will try to segregate everything and the components will go to exact measurements. It seems that it is enough to just hone the bushings. Teeth clearances measured and within the norms (0.06-0.3 and 0.12 is the norm). Some of the gear I have already cleaned and packed in foil (prepared for assembly). Camshaft perfect, head bolts checked and also already prepared in a box for assembly. Screws will go to galvanizing this week. The plan is for the bottom of the engine to be ready by the end of November. I've given up to the max and I think I'll look for a small sandblaster for my own needs. I tracked down a new, right door - and it's not that easy. They should arrive at the beginning of next week. I also experienced a shock when I heard the price of a Toyota parking lamp - PLN 744.20 per piece, and an oil pump with a plaster - PLN 3358.00. Who the fuck comes up with these prices A technologically similar part to KZJ-ota costs PLN 920.

13 Nov 2008

I found a whole set of new body bolts in Australia and clicked Buy it nowLet's see what happens. There is also a large package from Australia with mechanical parts that are no longer available with us. I also ordered a complete exhaust system from Belgium. The first part from the collector is not present in the replacement, so it will be the original. Fortunately, the rest is in a good quality substitute. From the important mechanical things, I'm still looking for a radiator. The water pump is already taken care of, I just have to wait a month.

13 Nov 2008

For now, I prefer not to think about it [the cost of professionally restoring the car - editor's note]. AK] but I can already see that it's not enough At the end of November I already have a window in the workshop to take off the kennel. Mechanically it will go quickly because I am gradually collecting lumber. I try to prepare as much as possible. A moment ago, more little things arrived (all filters and turn signal lenses)

14 Nov 2008

I got confirmation. A package with parts from Australia left today. 3-4 weeks and it will be. I also won a nice gadget at the auction in the USA - I will take pictures when it arrives and paste it. A new jack and a cover for tools will also be there. There are also other announcements in Europe with cool parts, but we'll see if they're still up to date. Thanks Czarek for helping Lopex also deserve thanks

16 Nov 2008

And on Sunday even I rushed to the workshop. The next elements are ready for assembly. Fuel filter mount and shaft seal bracket. Cleaned and packed in foil. Additionally, I started cleaning the patch with the oil pump. It is heavily soiled with oxides and dried oil. I put a few items in the washer to soak. I'll take some pics on Tuesday and post them. I've already started preparing the fuel dose control motor - BJ42 has such a funny patent

18 Nov 2008 [photo. 3]

Cleaning in progress. It's really a lot and it's taking up a lot of time at the moment. I still want it and I push myself in workshop dungarees. Another batch of parts has arrived so I have to complete the table in ExcelOjoj - it's getting a lot Karcher is in motion. All the time I sit with paper and pen making lists of needed parts. Even the filters are waiting. Maybe the assembly will go quickly then when I take the waiting parts and components. The rims will go to the sand in days. I have leftovers from my 70's which are exactly the same as they were in my 40's. I'll make a small exception here. According to users' opinions, Trailmaster springs are comfortable and convenient in everyday driving plus light off-road. I'm installing this suspension because the wheels will be a little bigger 7.50R16. A friend installed the OME and he is very hard.19 Nov 2008 (photo 4)

Cool things are made in the world. Prices are shocking, but no one said it would be easy. These are replacements made with extreme precision. I already have the originals: both front fenders and the right door. I'm looking for lefties. I've already tracked the windshield frame and the front grille. I need to order in November. Hard top goes to Emsie. The issue of the kennel itself will remain, but everything will turn out after sandblasting.19 Nov 2008 (photo 5)

This is what a galvanized shed looks like (not my car). I took this photo and watched it live. Unfortunately, I didn't like it very much. Corrugated sheet, bubbles and unevenness. A lot of work to prepare it for varnish. I will go for the traditional varnishing technique, only invest in good paint primers and chemicals. I guess TIG will also be playedOriginally, this was the color of my car, i.e. sand. It breaks down what would make it in olive as in the photo below. Typical classic color for a BJ.22 Nov 2008

The first shipment from the USA arrivedI'll take some photos on Sunday It's already been somewhere but I'm posting it to this threadThe so-called almost pattern http://1982bj42.com/23 Nov 2008 (photo 6)

Collected signs and stickers. I still miss two emblems for the rear part of the body (they come from overseas), a sticker for the air filter can (ordered) and a sticker for the fuel pump motor (I can't find it). I will have some for sale from the 2F petrol engine. I got it in the kit.24 Nov 2008

The sheet metal will not be so bad because I bet on the originals and the kennel itself is not in the worst condition. I used a screwdriver and there are no holes. We'll see what happens after sandblasting, but rather without a tragedy. The predecessor only replaced the rear fenders. The floor is all original. There is a 10x15 cm insert in the right wheel arch. On the right side there is a rusted one fastener of the kennel but it is easy to replace. Mudguards, frame, hood, grill and all metal sheets in the front are new anyway, so I will make a sale on Allegro.25 Nov 2008

Another large package with parts arrived today: - handbrake cable - sunshades inside - fenders - sets of gaskets for bridges and gearbox with reducer - thermostat - rear reflectors - covers of rear lights against stones from the side of the wheel arches - elements of the steering column - rubber overlays on the pedals - and a set of locks to fasten the window pane Another notice in the mailbox - probably this time Australia I'm a bitch but it sucks26 Nov 2008

The right door has arrived today - funkel new. I'm looking for lefties (original). For finding beer in Europe01 Dec 2008

A package from Australia arrived, but when I read the customs clearance procedures at the institution called Poczta Polska, I sat down with a breakdown and read the letter four times to understand anything about it. Printouts, authorizations, receipts, orchards, online transfer confirmations, translations This is not a normal country. Today the injection pump is going to be checked and possibly regenerated. It looks very decent after washing. The plant that will take care of it is located in Ołtarzew at ul. Poznańska 408A. I've done a few pumps there and I'm happy. Here you need an old practice - in-line pump. It should be simple to do. Final operations with cleaning the oil pump patch are underway. As the weather is nice, we will start the karcherek - it is terribly covered with oxides. I was looking for replacements for the cylinder liners, but unfortunately no one in Poland has anything like that on offer. Somehow I don't trust our craftsmen because they are available. The original ones in Toyota cost PLN 809.00 net per piece. I'm hoping to pass it on to other channels for half the price. If it succeeds, it will be fine. If not, I'm going to search in Europe. In Australia, of course, I found it but I don't know if I want to go through all the downloading procedures. The sun is shining and I chased BJ to work again. Mechanically, there really won't be much work. I confirm this belief with each trip01 Dec 2008 (photo 7)

On Wednesday my wife goes into battle. There are printouts and translation too. The list of needed parts will be given soon when I give up with my search. States are both cheap and expensive. My friends found me a few original plates, but the prices were cosmic. Not to say mega cosmic. Plus shipping and customs. It would be cheaper to buy a whole new body, which costs about $6,000 (motorboat alone). The plaster I mentioned earlier is hard. As you can see, the oxides stick to it and are difficult to remove. After many surgeries, it's still not good. This is the last item to clean. If it fails to work tomorrow, however, it will go to partial sanding. The springs and the entire suspension are also waiting in place. The pile of parts is already substantial. Many thanks to suspension manufacturer Trailmaster by Maas. They liked my idea and the suspension turned out a lot less with the support of our Partner. There will be no stickers on the car because it is not appropriate, but the full specification of the parts used will appear on the website. The appropriate tab "Project BJ42" on our website is already being created. The first elements of the body (the spare ones) have already been processed. A professional welding machine was rented for this occasion. The latest technology is in motion because my friend works in a large dealership where he undergoes various types of courses. He's good so they invest in him. Stainless welds, tin and stuff. He also mentioned something about copper. I don't know much about it, but he did something for me and I was happy. When the first effects appear, I won't hesitate to show them off.09 Dec 2008

Dunlop SP Sand Grip 7.50R16I insisted on such until my forty. Most wholesalers in the country have given up. Opponach com.pl says "buy now" but of course you can't buy them. Wanted size: 7.50R16 Only new ones or HZJ78 removed from a new one are taken into account, what someone bought and wants to change them.11 Dec 2008 (photo 9)

It is different with grammar packs. Especially with those from across the great water. One came yesterday. The goods were good, but the customs officer screwed up and I paid the duty on American dollars, not Australian dollars. I had nothing to say because it came in the mail and that's it. Now I have to unscrew a bit because as you probably know the exchange rate is not equal to the exchange rate. The other one returned to the AU. Only with us is such a brothel at the post office possible. The courier did not leave a notice because they pay them on delivery, so if he does not find anyone, he has a back. It is not profitable for him to issue a notice that the customer would pick up himself, so they throw it in the corner to try to go at a different time. Someone cleaned the corner and it went to hell. Now I'm waiting for it to reach Australia to come back to me - a breakdown In the meantime, a failure with the exhaust system. Ordered a month ago and paid in advance (otherwise they wouldn't). It was supposed to come from Belgium directly from Walker in two weeks. A small piece came yesterday, and there will be no more. Walker has finished production, I hope they at least get their money back. Today I met a very nice man and it turned out that there is another BJ42 (blue) near Warsaw, built since April last year. I saw the photos - mega gratification We agreed to talk with the camera so soon I will post photos. It is also dismantled into its first parts, sandblasted and assembled with attention to the smallest details. As mine will be dismantled on Monday, I took a few commemorative photos. On Friday, she takes part in a nice photo session with my seventy17 Dec 2008 (photo 10)

Well, it's happening. By Christmas, we want to take the kennel off the frame so that it will be sandblasted in the new year. There is an option to get the missing plates, so I hope to use it. We are slowly undressing the front. All the screws go in the trash. Unfortunately, the previous owner twisted the car on construction sites. Patents from the toddler also immediately find a place in the green container outside. In the first photo you can see how the car was painted. With plastics and electricity. Plus, vacuum and sip. There will be a lot of cleaning. You can also see the original color of the car. A few broken screws on the frame a few years ago. I'm waiting for drilling and threading. The frame will probably be nothing. You can see the effects of patching by predecessors on both sides. In addition, tar from the inside and sticking wires from the migomat. I have the impression that during the last renovation original sheets were used, but it will come out after sandblasting. Tomorrow I will open a new topic because I have photos of another forty built in the country. The initial state was much worse and it also made it19 Dec 2008

I walk around with a screwdriver and pick, tap and look into every hole. It turns out that the car has been varnished for dirt and old blemishes. Underneath reveals not rust but the original paint. Of course the sand will tell the truth. In closed profiles, and here a big plus for the predecessor is a lot of siuwaks for anti-corrosion protection. There is a clean sheet under it. On Monday the kennel will be placed next to the frame19 Dec 2008

The sides of the hard top are already made of bacon. Between Christmas I'm picking myself up. A friend who will be doing bodywork also touched the car. By the way, not only mine. Emsim sides are ready. It was necessary to bend the sheets because rust was everywhere - sandblasting the profiles inside. There were also a few inserts. They looked nice from the outside but it was also verified. Primed waiting for the rest. Some techniques of brass and tin were going away. Photos in a few days. Under the lamb on the frame there is a nice black lacquer. In places you can see the raid but without major pits. Unfortunately, the end of the frame will need repair - especially the spring mounting at the very end - it has delaminate a bit. The FJ40 car standing next to mine is beautiful. After the bodywork is done, it will be fine for years.20 Dec 2008 (photo 11)

Now you can clearly see how the car was once repaired. The varnish is even applied to the hinge seals (marked in yellow). When I look at different copies, no one wants to unscrew them Emsie and Wiluś are exactly the same. It is a pity because the seals are available only with hinges and these cost PLN 211 net per piece. The new hinges and the mentioned seal look like this. I will have all new hinges, but not from the native Toyota because I haven't completely lost my mind. They are much cheaper in the world. Many places are putty with rubber or silicone. All in all, it's even good because there's no tragedy under them. There are places of corrosion but not holes. It is also quite elegant under the glass frame. The seal is in very good condition so it will remain old after care treatments. Holes - no Lacquer laid on the muck. Even unswept garbage causes the claret to come off in patches. Stripped board and underneath dirt, vacuum cleaner and combined electrics. I removed a lot of redundant wires and it looks better. Even something like an alarm was in this vehicle - it seems to me. The soldering iron is probably an unknown device because connecting cables with a screw cap reigns supreme. After removing the additions, the original electrics are almost completely recoverable.21 Dec 2008 (photo 12)

This is more or less my direction of work. I will try to make sure that there is no crooked hose from the vacuum pump and that the aluminum elements are not varnished with a glossy, colorless varnish. The oil pan and pulley should be black but semi-gloss, not glossy. In the original there is a cork oil pan gasket, so the visible blue silicone also makes a small yuck(photo: http://www.ih8mud.com/)23 Dec 2008

Buda is standing vertically next to the frame Pics tomorrow because today from 2 am at work and I doze off a bitIt won't be easy but I'm getting more and more excited for this car25 Dec 2008 (photo 13)

As we want to do everything very carefully and not on a whim, I'm hoping [dealine is] late spring. If it needs to be extended, it will. So far everything is going according to plan. Even if I wanted to speed things up, I couldn't. Toyota Polska, a warehouse in Belgium, has many things out of stock - they have been withdrawn from production. I have great fun with construction and it turns me on. After removing the hinges, it's not too bad. I discovered the mystery of the painted gaskets on them. Well, the rubber seal is vulcanized with a new hinge. After removing all the elements from the front bulkhead, perfectly preserved damping mats were revealed. Before sandblasting, I will make templates to recreate them exactly. There is a mess under the jack mount. This is the only hole in the body that can be detected with a screwdriver. I wonder how much it will be after sandblasting. Sławek from the tinsmith was there yesterday and he said that it's not bad at all. We made some decisions and another view of the rear part of the kennel stripped down to the broth. The rear beam and the kennel fasteners are healthy. Either they remained intact from new or the repairer replaced them with the original ones. Pillows, screws and washers between the frame and the kennel are quite a bit of rubble. I hope Emsi didn't buy the last set, I suspect they are universal from many Toyotas and there will be no problem with that. Most of them got away. On the side of the frame, one fastener is rotten and will require welding a washer with a round hole. The front part of the body from below is almost perfect - at first glance. Worse with the back but no tragedy here either. These darker spots are oil with grease and under it a perfectly preserved sheet metal with the original varnish. And the doghouse placed vertically in all its glory. I'm going to tinker with it a bit between Christmas. I need to rivet the nameplate, trailer and sand. The guy who will do it has experience. We give it all our components and you can still see all sorts of old cars there. Dawid, being there, even saw an old Mercedes with the doors opening up. It took Mariusz (he was working practically alone) four days to get to this state. At the same time, there were breaks because other cars also have to be done. We planned a special date for this in the workshop. Since January, I've been wearing dungarees again because there's a queue of cars from here to Piaseczno.

29 Dec 2008

From the moment I became interested in Toyotas, the J4 was my dream. As you know, dreams do not come true right away and you have to wait for the right moment. It will be a car built with passion. I used to put together Beetles with such passion and it worked. So it will be now. Once my first Beetle wanted to buy a VW dealer in order to put it in the showroom. I was young and I enjoyed it for myself, although the money offered was not small. Then I renovated another Beetle and it sold in one day for the price of my then 5-year-old Land Cruiser. Then five years ago there was my Toyka, but a real renovation awaits her after forty. I have bridges and many other elements in it. They were sandblasted, varnished and assembled on new components. Two years ago we made this vehicle. It is a pity that without removing the kennel, but that was the vision. Nothing for hooray29 Dec 2008

Every second part is no longer available in our ASO. Today I fell on a few small things from the fuel system. I ordered the worn covers of the transmission rods and clutch paws. My ordered lumber from Aisin has arrived but I don't know if all and how many pieces. I order engine and gearbox mounts in Australia. Parts prices are going up. Several foreign partners have already sent new higher price listsASO also raises prices At home after work, Cif went into motion. The cleaning of the plastic elements of the interior is gone. Tomorrow I will post before and after photos01 Jan 2009 (photo 14)

And cleaning is done with such accuracy. The photo shows two similar elements of the plastic heating system. One before cleaning and one after. As you can see, the varnishing was also leaving without protecting the interior elements. Fortunately, varnish was put on the beard, which now allows you to clean these parts nicely. Cleaned elements are wrapped in foil and will be waiting for assembly. The top piece of the pipe looked exactly the same as the bottom one05 Jan 2009 (photo 15)

Small and Liquid. Pictures of the same parts before and after cleaning. Today the first Aisin lumber specially ordered for us arrived. I have already removed the entire internal heater. Here you will see the differences08 Jan 2009

More pieces of the puzzle have arrived. A few gaskets and the original antenna for the radio. But these gadgets are fun. I can also assemble a complete license plate pad. Everything from the smallest pieces is new. The old one could not be restored. I'll post pics of the old and new for comparison. Repair kits for rebuilding both heaters (sponges, washers and various gaskets) come from the USA. Someone is making it because these items are not available as spare parts.Jan 10, 2009 (photo 16)

It's not good. I got the keys to the house and I make stuff in my free time. The license plate base is one of the completely new elements, assembled from several separately available parts. As I wrote earlier, the old one is rusty, smeared and has redundant holes. You can even see the screws from space that fasten the visors. Each differenti for a flat screwdriver. The lamps are damaged, including the galvanic coating. After analyzing the costs and aesthetics of possible regeneration, it was decided to buy new. Lots of other items and parts. For comparison, in Poland a gearbox pillow costs PLN 857, and there, after customs duties and VAT, PLN 325. And it's by airmailJan 11, 2009

I'm also curious about [the final calculation] I already have a lot of stuff and I'm close to the price for which Emsi or Wiluś bought the car. I save everything in Excel. Every expense, part numbers and where they come from. Mechanics shouldn't surprise me much. The gearbox was flawless, the engine is dismantled, bridges are like bridges - they are not a secret to us. Please note that with the car I still got a whole complete second engine.

Jan 12, 2009

Well done to whoever finds a new gear knob. There is no problem with the four-speed gearbox. It's about the five-speed Toyota ended productionJan 12, 2009

Unfortunately, not such a thing (link) The original is plastic with a gloss and a plate at the top with a black and white print with the gear system. I think I'll buy myself a brewery because I ordered a scoop in the Emirates. Will be back next week with other little things. I connected with an order for an air shipment of a friendly wholesaler.Jan 12, 2009

Useful links (Borysia's post):

http://coolfj40.stores.yahoo.net/index.html http://www.cruiserparts.net/shop/ http://www.ozeastfibreglass4wd.com.au/gallery.html http://rockym .fatcow.com/store/steel.html http://www.sor.com/ http://www.toycruiser.com/index.htm http://www.qldcruisers.com.au/index.html http: //www.buschtaxi.de/ http://www.aqualu.com/aqualu_industr..._05-08_003.htm http://www.roycreations.com/ http://www.diebo-teile.de/znp /toyota_landcruiser_j4.htm

Jan 12, 2009

They do not have . SOR may have a stimulant, but I also have a wiped one. I've known most of the addresses for a long time. In America, as it turns out, the reconstruction of J4 is not so cheap, and the transport costs kill. The other thing is that they have something or make some extra money. I've already found the same parts much cheaper in another part of the world. Borys - the brewery deserves credit for the time spentJan 12, 2009 (photo 17)

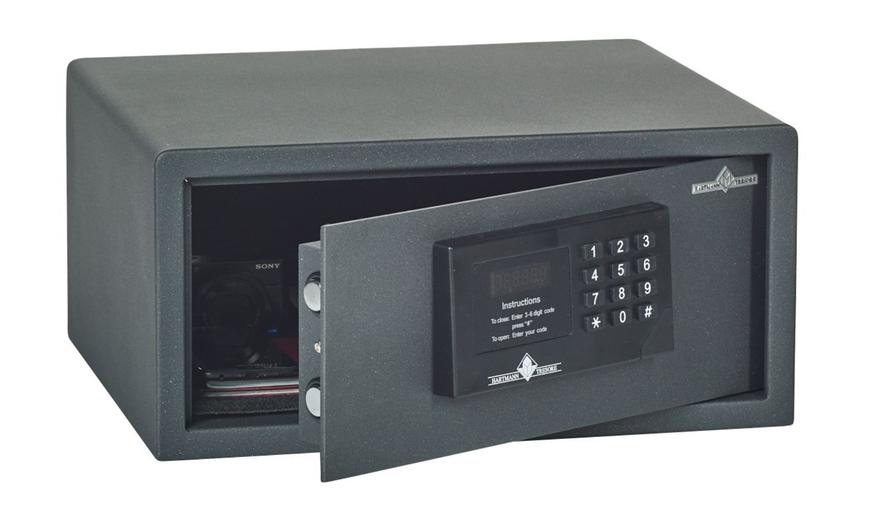

Time has slowly come for the brakes. I have already presented a photo of what the calipers will look like after regeneration - the premiere in about two weeks. Many people have chosen to do so and do not regret it. For the third year in my KZJ they run and it's great. No problem with seized pistons or downloading during braking. Below are photos of the calipers removed today from the forty. From the outside, everything looked ok, but after removing, they cry for vengeance to heaven - it didn't even cross my mind how you can do the brakes. The fact that the pads could fall out is of little importance. Out of four safety bars, there were only two and they were different (some made from another car). Interestingly, one of the pistons was installed backwards. Since there was no groove in it in this position for attaching the protective elastic, a wire tied in a knot was used. In the second piston, the rubber is held by furniture screws. I'm shocked and don't really know what to say. Fortunately, the pistons and erasers will be new. I have marked the interesting facts with red arrows.Jan 16, 2009

And I have more lumber: - connecting rod bushings (original) - tappet glasses (original) - fuel line (original) - a set of springs and pins securing the brake pads in the calipers (replacement) The sheet metal is macabre, actually with one German company what is like he has them. I found a window frame in a germany. Used but apparently no rust. I am waiting for photos. As I already have a new exhaust waiting, a piece of my old one will go to the Czarkowóz. Sandblasting is still waiting for positive temperatures. The price of sandblasting is not small PLN 170.00 per hour. There are cheaper guys but these guys make old cars and take it all in.Jan 16, 2009

The worst thing is that you can't calculate the hours in advance. For small parts, I will buy my own cabin sandblaster. Buying is cheaper than paying for items later. The general cargo is counted per item, not per hour. This is the case at least in a few in Wawa. Some people are still fussy when they see powder coating - I don't have it. There is a nice sandbox on ul. Rosy but the dates are cosmic. You leave the parts and they say ready for tomorrow. Then for two weeks of fighting and they can still lose something. Mega behemoth and when picking large orders, they push small.Jan 16, 2009

I will sandblast in Wołomin. On the known one, I gave 15 winches for sandblasting with plates (in elements) and that's how it turned out. There's a lot of rust left. The Lord explained it with poor pressure at the nozzle.

Jan 19, 2009

The coveted screws came the aforementioned stuff from Toyota. I'm going to balance the shafts tomorrow. Only one cross and spline in the front shaft need to be replaced.Jan 21, 2009

More little things are piling up. Door panels, reducer knob, rear door seals. Most German companies are a huge scam. They deceive for weeks and nothing. Instead of saying that they don't have sheet metal, they make it dark, that maybe they are, maybe they will be, they have to check, etc. We've been trying with Czarek for a month, or rather he's the one to come to an agreement. They don't speak English in bangla or they don't answer emails. They work two hours a week. I was pissed. I'm going to take the alternator to rebuild tomorrow. There will also be a large majority of lumber from the engine, so the assembly will begin. I'm just waiting for the bushings.Jan 21, 2009

But the number. There was a guy on Ebay in the US who was selling junk up to forty. He had quite a lot of it and as far as I remember, since September he had a lot of offers. I ordered something a few times and it arrived. In fact, somehow late and with a lot of slippage and not the fault of the post office, but rather him because I saw on the stamps when he sent. I made another - this time a larger order. As always, I paid with Paypal, and after two weeks, here comes the info from Ebay that the guests have closed their accounts for breaking the rules, abuse and other actions that they will not inform me about for the sake of the investigation. Please do not send money and e-mails to him. Nice. I wonder if I dipped over 200 bucks. I'm even more shocked because he had several hundred positive opinions and even managed to give me opinions for fast payment. Browsing the net you can find the same parts as in coolcruisers, only cheaper. They have a lot but too expensive shipping. As it turns out, window frames in most restored vehicles are made of laminate . 280 ojro and you can buy it. However, I insisted on the original and I fight with a drug in good condition. As I wrote before, I'm still waiting for the promised photos. Apparently - no rustle, but I don't think I'll wait.Jan 22, 2009

I'm in shock. I just got the photos of the frame. Frame bought. I'll post some better resolution pics as soon as it arrives. Shelves for refurbished parts are ready. In two weeks we will start filling them.Jan 22, 2009

The side door seals were made in Taiwan and came from Australia. I must admit that the workmanship is ok. The rear doors are to be original, but it depends on the course of the auction. I did not expect that in the original the seals are glued, and not inserted into the gutters as in other Toyki. Well, you're learning all your life. The sun visors come straight from the warehouse in Japan. But they must be surprised there. There is a crisis in the world, factories are closing, and here Poles are buying antiques from warehouses. Yesterday I watched Toyota reports on TV and it went poorly - like others with the rest too. In such an old vehicle, it is worth checking all rubber elements. After careful inspection and tinkering, it turns out that many of them need to be replaced. Here you can see a very good example of a broken gear stick rubber. It's new and waiting. I also qualified the cover rubber of the 4x4 drive engagement rod and the missing rubber of the clutch paw for replacement. The same thing happened with the rubber connecting the steering column with the gear - oh that was the way. When it comes to the front part of the interior, I'm looking for elements marked with red arrows. I used photos from the internet. I'm talking about in good condition. There are no knives. I found one board in the states, but transport is unprofitable, and the purchase costs are very high. Two days ago in Bemowo I saw another 40 nicely restored with historic numbers. Olive yellow color. On Monday I will dismantle one rear door and give it to be sandblasted - just to check. I'm afraid we'll be resuscitating them.Jan 22, 2009

One of the arrows will probably become obsolete tomorrow. I'm pushing for parts to assemble faster in the spring, and not stop every now and then in search of lumber. Painter already selected.Jan 23, 2009

There was a slight acceleration and the door hit the sand today. I'll post pics on Tuesday. The transversal board is also already tracked and selected from three, so the upper arrow is out of date. On Saturday I will finally drive up to take photos of the finished hard-top sheets. In two weeks there will be a significant acceleration of work because the car is coming to my house so in the evenings you will be able to tinker. As a body and paint support, I will have people who know their stuff. They deal with restoring old cars, but about that in due time. I managed to buy a set of new locks and an ignition switch at a good price with one key in AU. Only a part is available in our Dealership. Plus it's expensive as hell and I'd need a separate key for each door.Jan 23, 2009

I'm going further with coke. The first two photos show more or less the condition of the hard top plates. Rusted holes on the bottom and rivet holes on both sides. After removing the layer of paint, a lot more rust appeared. Even in closed profiles, ore lurked. The visible edges have been folded back and the surface underneath them has been sandblasted with a small gun. Then it was secured with some good pacip. And so, at a later stage, all closed profiles will be impregnated with a special anti-corrosion agent. Virtually all corners required repairs. Even fragments of internal profiles were replaced, preserving bends and sheet overlaps. A trained eye will notice the inserts in the photos. Both elements with welded rivet holes (corrosion-resistant weld) will be thoroughly processed and corrected before painting. At the end, some fragments are sandblasted and varnished. To be clear, there is now a smooth surface on both sides of the sheet in the places of holes. The rear doors and front grill will be repaired after the weekend.Jan 26, 2009

Well, tomorrow everything will be clear with sandblasting - pick up around noon. I gave the door for testing but as a result of today's new contacts, the place of sandblasting will probably change. It's good to listen to people with many years of experience in rebuilding old cars, and I now have such behind the wall. The screws for turning the engine have also arrived, it's a pity that out of thirteen identical four are brighter (9 in yellow zinc and four in white) - somehow we'll give ourselves I can handle that. Still waiting for the missing bushings. Auctions with trinkets went well and another batch of cool stuff is coming from the USA.Jan 27, 2009 (photo 21)

Shafts readyJan 28, 2009

Nice message has just arrived. Some of the stuff from the Arab Emirates will soon be available for pickup. The first batch is small but there are a lot of them. The set of necessary lumber is slowly being collected. Because it's warmer, I'll start unscrewing nice screws from two junkyards in my yard - and put them in a box. They hadn't sandblasted the door yesterday. Maybe today.

Jan 28, 2009

Tapeworm continued. The door has returned from the sand. I have to admit I'm not entirely satisfied. Everything in this car is supposed to be tip top, so there will be a fix, but after the first bodywork repairs. It didn't cost much - 50 PLN. It's good that only one item went to the test. The visible white cake is putty. I don't know why it is because on the other side the sheet is perfectly flat. It was not torn off by the decision of the sandblaster. Here you can see the previous repairs. Inserted square and welds instead of welds. We'll do it our way. A new or improved square and a return to welds without visible smears. The fastening of one hinge also fell victim to smears and corrections. We can do it. The tinning will go on. As little putty as possible. You no longer wanted to work inside as much as you can - and you can. The visible black stripe is the original rubber sealing the bent edge of the door. Smears, Smears and more Smears. We will eradicate the plague. There is also a mess to improve here. A clever patent for rim repair. The pit will be cut out and rebuilt anew. I tried to buy a new door, but getting them is a miracle. This corner looks good. It's a pity that I have to correct the lack of sanding. That there would be no continuation soon because, after all, there is still something going on. Sheets from Germany arrived today. Internal and external mudguards. I still rely on the originals. Other sheets will go to the next forties. There is already a bit of that in our country.28 Jan 2009

And the first hit. Ebay failed to close the case of a missing package from Australia. The sender proved that he sent it, and that it was lost it was difficult. Embedded AU$99.Jan 29, 2009

My car will be on Trailmaster suspension with OME hangers. I wonder if Dobinson also distributes hardness to a car with a hard top or a soft top. I need to look at the catalog. Coming back to the photos, next week there will be better conditions for it. We'll make a tapeworm out of the new suspension, the waiting plates and stuff.

Jan 29, 2009 (photo 23)

Do you remember these terminals .viewtopic.php?f=35&t=851&start=135Now exactly the same ones look like this. The postman brought a small cardboard box with kits for regenerating the heaters. It was a package sent by a guy who was blocked by Ebay. As you can see, I was lucky and got paid lumber. He even asked me for five stars but the admin even blocked it.29 Jan 2009

In a moment, in a moment .... the alternator and starter will be spinning. I mean, they're going to look like clamps. Not to mention the steering gear and the wiper motor.30 Jan 2009

Toyota introduces further cuts. As a result, I had to speed up shopping and make decisions too quickly. The handle has fallen. I went with the engine for a long time.02 Feb 2009 (photo 24)

The United States is a vast mine of parts that are hardly obtainable in Europe. In ASO, they said the end of production, and the price was visible from space. Another parcel has arrived. We had to go to the post office, but a box full of surprises arrived at no extra charge. It's nice because I negotiate prices with the guest and send very quickly. Original sets of rear door seals, reducer lever knob and, most interestingly, an accessory lamp. A special socket for connection is inside the glove box. Cool gadget. The package arrived in a few days.04 Feb 2009

I'm currently having a scuffle with one guy in the US. I won a light trinket on Ebay for $86, and he gave me almost $300 for shipping costs. He supposedly checked with several companies and so it comes out. I also found a nice sheet metal manufacturer. They look like the originals, and strangely enough, the front grill is shipped for $74. The seller, proven several times, also tries to arrange for me a few trifles from the interior equipment (including the famous gear knob for the five-speed gearbox). The engine is waiting for the bushings, but apparently they arrived yesterday - thanks Jacek. If they are assembling the engine will go fast. I'm also waiting for the head and pump from a certain engineYesterday I got photos of the FJ45 Pick-up built in Poland and I have to say that things are happening in Poland when it comes to the forties. A friend from Legionowo had temporary problems with a tinsmith, but the work continued. Yesterday we delivered more sheets.04 Feb 2009

The sleeves have arrived. Other stuff cleared yesterday, and today the postman brought them early in the morning. But this is coming.04 Feb 2009 (photo 25)

Not bad. If I had ordered bushings at Toyota a day later, I would have been in the back of PLN 497. Toyota has raised parts prices again - fucking crisis. More seals, door handles, interior grips, engine and transmission mounts, and speedometer cable.05 Feb 2009

Yes, someone mentioned that there were two such transports to Poland, but he wasn't entirely sure. It was actually Mag. On Monday I will try to fail the second door to the recommended sandblaster. Maybe you can also unscrew all the undercarriage covers. They are in very nice condition so after sandblasting there should be no holes. In the new store, I have prepared racks for arranging components. At home, the mountain of boxes grows mercilessly. On the Allegro I bought a new Toyota funkiel thrust bearing. The price at the ASO is PLN 248. I bought it for PLN 60 - thanks to Czarek, who invented it (Czarku no stress - yours was different). There's a drought on Ebay - at least the European ones. Of course, there are a lot of lumber behind the water. I am waiting impatiently for the shipment with the glass frame and the board. The Italian found by Borys doesn't write back - it's a pity. I'll try from a different address. I'm starting to regenerate the heaters. I already have all the items. Photo report on days.06 Feb 2009

Fewer and fewer, unfortunately. Rust is merciless to them. There are fewer and fewer parts on the market. Fortunately, there are still a few freaks in this world that keep them in good shape. Yesterday we watched cool photos with Wiluś and more visions were created in the banya. When I finish my original, I'll buy another one and I'll do it without preserving the original but with flavor. Why. Wilusiowa is also taking on a look. The back door is doing. Unfortunately, the next package went to the customs officers - a set of locks with an ignition switch arrived. On Saturday I'm painting the walls, but next week I'm going to change into my work pants to relieve stress.06 Feb 2009

Returning to the head. Mine, as I wrote before, is not suitable for use. It will create some gadget for the new shop. The engine block from 1KZT has its place. The photos below show the exact reason for her disqualification. I marked the visible crack on the vortex chamber with a red arrow. This is what the first cylinder looks like. In addition, numerous pits resulting from the burning of the material can be observed. Water also had an effect. It was probably getting into the cylinder through a crack between the valves. The gasket looks correct and original. It is metal, so blow-bys are very rare. The pistons are intact, which will be thoroughly checked anyway. In the second engine I have almost new injectors, so after checking them, they will go to the overhauled engine. Someone replaced the whole thing, not just the tips. The other three cylinders look correct. The third and fourth photos. Nevertheless, I will not risk installing such a head.09 Feb 2009

The window frame has arrived. Most of the frames in these cars are unfortunately rotten or patched in many places. You can buy a replacement laminate for 280 Euros, but that's not what this project is about. was supposed to be the original. For almost two months I was deceived, actually Czarek in the Keba company and I don't think I want to check anything there anymore. Pity. Seemingly so nice at the fairBelow, for example, I gave a photo of the frame from Michał's car - it's not the best. Mine is in even worse condition, which I described here: viewtopic.php?f=35&t=851&start=75I took the risk of buying a drug over the internet. We found one in Germany. After a few days, I received not very clear photos taken probably with a phone. A short exchange of words and we order. It's supposed to be rust free. In addition, in the garage of the seller there was a board that I have in not the best condition. There was a quick bargain another photo from the phone and here it is. As we receive a few parcels from abroad, the shipment came out not too bad. A decent friend from Germany didn't even want to give the package to the courier when he forgot the company's papers. He asked by e-mail whether this and that company should pick up the package. My friends wrote to usAs you can see in the pictures below, the purchase was good. Brand new original frame once varnished on the original black primer. Well, and the board. I was supposed to get it or buy it from the rock & roll car factory, but the decision-making process seriously failed. The upper one is new (stimulant), the lower one is old. Apart from the farfocli, the bottom is significantly warped. This is the middle element of the old one.10 Feb 2009

I guess I need to slow down with these purchases. I won more auctions. Vent seals, interior light, door handle parts and a few other bits and pieces. And the topic of used parts from Germany is developing nicely. If it goes on like this, more elements will be available for use on the walls of the new shop. We shop for several cars at the same time, so the costs are spread out. It seems that stage II will be ready sooner than I thought.11 Feb 2009

In the past, there was no option to view the goods in advance via the Internet. Today, trinkets can be downloaded from all over the world. Worse with large things - costs. The biggest problem is still the damn plates. Camshaft bearings arrived yesterday. As if they didn't need to be replaced, but if grazing is grazing. Replacing them later without disassembling the entire engine is unlikely.

Feb 11, 2009

I once mentioned winning an auction for 86 bucks and high shipping costs of 289. I found a solution today. For 20 he goes to another address in the states and then to Poland for 64. Another paranoia is, for example, a mask. A brand new Toyota is $600, and shipping is $2,400. Let it stay where it is. We'll find a way to deal with it soon. Not such things from this America come for pennies12 Feb 2009

The topic of the mask is solved, as well as a few other gadgets. The US has lost its chance. The mask goes used in perfect condition, so is the case with many things from the equipment. Wanted armrest, rear carpet and even the original tool cover. Today ended with the resolution of several problems related to further reconstruction. As of today, the end of shopping when it comes to equipment, small items, etc. - until the assembly of the car. I'm just waiting for a few shipments already ordered and sheet metal. Looks like 40 will take me some time13 Feb 2009

I gave the second car for parts, and then for a dream car. How to have fun is to have fun.February 14, 2009 (photo 28)

As I wrote, it happened. There is a blue BJ42 for parts to support the BJ42 project - for the original. 1981. The purchase of this vehicle practically solved all problems with finding parts of the equipment. Original mileage 135,000 km. The car belonged to a Toyota dealer in Germany. I will have pics of the loading and I will post them. Most of the car has original paint. A few holes in the backside. It has a damaged engine. I have no idea what happened, but the head is removed and, unfortunately, left for several years. The car was parked in the parking lot and the cylinders were catching ores. I suspect the head gasket blew, but on the side of oil lubrication. The whole engine is in oil, which preserved it perfectly. I'll take a good look at it on Monday and do an inventory of the lumber. For now, the parts are in a cardboard box in the trunk. Even the carpets are in great condition. The mask has not a single rust bubble or a gram of putty. It has original paint and soundproofing in great condition. All elements of the locks in yellow zinc. Mine already had a patent from a toddler and bent tendons. There are a few millimeters of putty on the bonnet in a few places. Now it will be much simpler hence abandoning the search for an original new mask. The lower edges of the door are a bit rotten. I have bought the sides and they are on their way, but please see what condition they are in this car. They will not be wasted. the middle - a dream. My maroon screws will go to the car in sticks. To the burgundy from here. I was looking for this console. It's like it was fitted at the factory yesterday. Someone managed to tastefully paint mine in metallic graphite. The condition of the roof and headliner - no comments Rear seats. To replace the stripes (I have a brand new one) and a sponge so that they stand up on the corners. You don't even need to paint them. Everything is original. I don't have to regenerate half of the things anymore: heater, wires, pull rods, pedals, etc. Everything is ready for assembly here. Papers found in the glove box: car manual in German, radio warranty and soft top installation manual. I wonder what else I will find because I had little time, and the glove box is full of papers. The engine compartment is a real miracle for those years. Virtually no rust. Fenders like new. Electrics in perfect condition, original batteries, all nameplates, erasers, pierdółeczki - just everything. Translating it is pure pleasure and a lot of money saved for rebuilding in the previous vehicle. Elements after cleaning will be transferred to burgundy when the sheet is made. This car has a very rotten rear and visible repairs everywhere, i.e. rear fenders and inner wheel arches. Perhaps the entire front will be used for mine, however .....15 Feb 2009

Before that, she had been rallying for a few months. The owner wanted to renovate it for himself, but the crisis came and the price dropped seriously. As of today, it is not for parts for resale. New mats in ASO are terribly expensive, and probably not even available for this model. For my seventy, it costs something around PLN 1200.

15 Feb 2009 (photo 29)

Cleaned cover. I was so excited by his presence that I didn't manage to take photos of how dirty he was - and he was. Unfortunately, traces of rust could not be removed. The slider works flawlessly. Perhaps there are still tools for the set somewhere in the car. The jack is.Feb 15, 2009

And I have internet http://www.ericleblanc.com/gallery/g2da ... 20bj40.jpg http://members.iinet.com.au/~ironpaw/bj ... iagram.pdfhttp://forum.ih8mud. com/diesel-tech-24- ... -glow.html

Feb 17, 2009

I did a little hardware inventory. Of the papers, apart from a few telephone cards, there is practically nothing. There was something else from the radio. I discovered that the original brand new frame beam with spring mounts is mounted on the rear. It rots routinely and is also rotten in the maroon one. Now all you have to do is translate. The rear part of the car was made after the floor is not sensational, and the inner wheel arches are made of flat sheet metal. The entire front, interior and top of the car are perfect. The front door is for recovery. No putty and just weld the repair kits. Thanks to the blue forty I have much less work and shopping. It was a good move.Feb 18, 2009

For me, all the equipment is important, seats, roof, wheel mounting, the entire front to the front sills, rear beam, radiator and engine accessories. The rest does not matter because, as you write, it is rotten, which does not mean that it should be thrown away. Gearbox, bridges with a mileage of 135,000 km also do not walk on foot. Today all rubber bonnet fenders and camshaft bearings arrived. I receive my first items from the Arab Emirates on Monday.Feb 23, 2009

Temporary break in work due to stage oneToday, Sławek and I decided to resuscitate the back door of the blue Toyota. They have holes but there is a lack of professional previous repairs and putty. Maybe Brzyd will be able to buy something from parts in Libya - I gave him a list but he will probably forget. By the way, it turned out that in 1981 the rear doors had three hinges (and some modification was made), and in 1983 only two.26 Feb 2009

Finally, today the ignition with locks from Australia and a set of parts from the Arab Emirates arrived. Unfortunately, they gave the gear knob from the modern HZJ-ot. I bought the entire fuel filter mounting with the connectors and the filter cheaper than in Poland.02 Mar 2009 (photo 30)

The work stopped a bit due to the workload in the workshop and the new shop. I spend almost every spare moment there. Next week, the opening so BJ-otka will return to the wallpaper. Now I'm uploading a photo of the recently arrived lumber. A few little things but useful. I will also try to take pictures of the accumulated plates in the next few days. The rear right door is almost done so I'll post pictures as well. Primer varnish purchased and waiting. New sandblasting is in Choszczówka, so I will be close on my way to work.04 Mar 2009

Today the postman brought ventilation flap seals, reducer lever cover, interior lamp and elements of door handles. Small and happy. Tomorrow we will still work in the field, but next week we will start with the engine. Photos and full technical description will of course be pasted.04 Mar 2009

Oh, a hen's melody. My car will have components manufactured and purchased from ICON www.icon4x4.com. WhatMar 12, 2009 (photo 31)

Last little shopping. The sun is coming out from behind the clouds more and more often so the sand action is getting closer. Modlińska is slowly starting to work, so there will be more time for forty. I'm a little behind on the topic, but that's the way it is sometimes.18 Mar 2009

Well, the first boxes with new ones have been opened. On Friday I pick up the engine from replacing the cylinder liners. The camshaft bearings will also be replaced. The big assembly will start on Sunday, but before that I need to buy heat-resistant gray paint.19 Mar 2009

Measurement result - all git. The shaft is only polished. Pickup tomorrow.Mar 20, 2009

Received . For: - measurements of all bearing shells and pistons - polishing of the shaft - spacer of cylinder sleeves - replacement of connecting rod bushings - replacement of camshaft bearings Everything remains on the denomination. Keeps the dimensions perfectly. Apart from the bushings that went new with Genuine Parts. I paid PLN 1100.00. The guys seem to be starting to raise prices because less engines are made and more just replaced.22 Mar 2009 (photo 32)

I went to work on Sunday to tinker a bit with my baby. The guys picked up the engine block from machining on Friday. What they did there I wrote in the post above. Neighbors on Szczęsna looked at me like I was a moron. I fought with Karcherek and the engine block for two hours - on Sunday. The water was pounding side to side so that I was soaking wet after half an hour. I turned it around on the stand and cleaned the dirty places again. I even gave myself ecological chemistry for this purpose. The goal was to rinse out the smallest dirt. Then I degreased everything with Wurth brake system cleaner. Then the compressor warmed up red because even the smallest droplets of water were blown out with compressed air. Then again Wurth. As you can see in the attached picture, the block is clean and waiting for assembly. The block shows fragments of the original color. Not black, but grey. Same for me, that's enough for today. I made samples of two shades of gray. As you know, the lid is always a different color than it actually is. I painted the lower part in a light shade and the lower part in a darker shade. After drying it fell on a lighter gray. It is very similar to the original. I sprayed the rest on light and waiting for it to dry. During the week, I will glue what is not to be painted and finish the painting work. And the characteristic marking of the 3B engine, i.e. the rounded capacity of 3.4.25 Mar 2009

A great sorting of new parts has begun. I pulled out cardboard boxes, parcels, boxes and bags. I'll try to take pics of the pile. First, I separate the engine parts to assemble the engine. Pieces from Icon are already in Lodz (thanks to my friend Bekon) but from the description I don't know if there will be a great disappointment with the American legend.26 Mar 2009

I went crazy and ordered all new bolts to screw the oil pan and water pump. Another engine assembly on Sunday. Lots of work to do.28 Mar 2009

I was supposed to make a pile of parts, but total lack of time didn't allow me to do it. Today during the day I managed to take photos of the new original plates that I have collected so far. As I wrote earlier, the front hood and the window frame are in perfect condition from stimulants. The same applies to the front grille and mudguards screwed to the fenders visible below. Rear fenders and inner wheel arches come from good quality replacements made of galvanized sheet. The left door will be repaired as well as the rear one (right rear door is ready). Well, unless a miracle happens and I get new ones.

Mar 29, 2009 (photo 34)

This is how it is lately that a man has a moment of time for his hobby only on Sunday. In a week I'm taking a vacation to catch up with work, Marcin will come back from Libya and take care of Modlińska. Last week the engine was washed and I chose a shade of gray. It's nice because after drying it darkened and came close to the shade of the original. Now it remains to protect the smooth surfaces where the gaskets adhere before painting. As you can see, I used regular masking tape and a small hammer. As in the past, paper gaskets were made, so now I cut out the appropriate shapes in the tape. Finally, the last degreasing and off to work. After applying two coats of paint, I removed the tapes. Currently, the engine is drying and waiting for further moves. However, it will probably also be possible to get the original one rear door. I found them in the USA but the transport costs kill. A colleague of a friend came to the rescue (thanks). I met him today to pick up bacon. They flew with him from Chicago in a suitcase. Pics tomorrow.30 Mar 2009

On the previous page, photos from painting the engine. I also analyzed a lot on Sunday the purchase of a blue BJ-otki. I walked around it, looked inside and even sat in it for a while. It was a good buy. It saved me a lot of time looking for trifles and spent finances. The engine, although damaged, is flooded on the sides with oil (it was leaking from the head gasket), so it is perfectly preserved. The cover of the oil cooler, which looks bad in my engine, will be taken from it (every screw shines after washing the oil). As soon as it gets warmer, I'll start preparing parts for the maroon one. From what will be created Monster BJ42 - the decision has been made.30 Mar 2009

There are two options. Either the 3B engine with the Turbo system, which I am already importing from AU, or something petrol will remain. When I'm in Australia, I'll wear the company Terrain Tamera (400 KM) - they have engine mounting kits from Chevrolet for it. Well, this topic is about the original, so if I start tinkering with something, I'll create a new topic.30 Mar 2009 (photo 35)

All that glitters is not gold The first disappointment of what I ordered online in the US came. Famous door panelsFirst the joy of winning the auction - $ 86, and then fighting for shipping costs. The seller - Icon, requested $ 296 for the shipment to Poland. Almost a month of correspondence brought no results. I broke down when I calculated the whole thing plus duty and VAT. Bekon's friend came to the rescue (many thanks). To him, Icon sent the bellies for $ 20, then they arrived in a suitcase by plane. He already told me over the phone that they look like this. The description of the advertisement showed that these are "aftermarket" sides, but they are deceptively similar to the originals. Unfortunately, only in the photo and from the front. As a result, they are made of gray lacquered plastic. It may look nice, but even before putting it on, they are bent and cracked at the corners. Such a slightly weak replacement for something that is supposed to pretend to be BJ42. Due to the lack of a good original, I will probably install them, but I am looking for OE. My right one is blue. The left one is slightly torn from the bottom. So watch out for great sides from the USA.01 Apr 2009

Passion develops. I have a nice copy for sale. I need to clean it a bit and put it in the salon on Modlińska. Fire brigade . Since the sun is shining from the morning, I bombard the phones of the recommended sandblaster with what to do next week. Unfortunately, the phone is silent02 Apr 2009

On Tuesday, the kennel is going to be sandblasted

02 Apr 2009

And it turned out even better. I mentioned that behind the shop on Modlińska there is a workshop dealing with the reconstruction of old cars. A Ford T fell out of line and probably tomorrow my kennel will go to their own sand pit. It couldn't have been better. We agreed with Mr. Piotr on the details and the work will start in full swing. IM so happy. On Saturday, the assembly of the painted engine is continued. Transport scheduled for tomorrow02 Apr 2009

I thought I would refrain from buying more parts but this is stronger than me. I ordered a few days ago brand new bolts to screw the oil pan. Well, they can't be ugly and rusty with a repainted engine and oil pan. Today they arrived at Szczęsna. I'm browsing the EPC and every now and then I click something. As we are now the first hand in Poland of the Australian company Terrain Tamer, the entire gearbox and reducer repair kit landed today at the customs of this company. The sets are based on good quality Koyo parts and bearings. Virtually all mechanics are now available from us within 10 days. Originals, substitutes whatever your heart desires. The guys are suppliers of parts to the most famous American and French companies. So now lumber up to forty will not cross one ocean more in two directions. They have been sweeping the Australian market for forty years. It is their company forty that has 400 hp. What this passion can lead to. Yesterday, when I saw Radomada's forty, my heart was beating faster.03 Apr 2009

But it's a nice feeling when a person is typing on a computer and with the door open you can hear the work at the shack.03 Apr 2009 (photo 36)

The machine started sluggishly along the rails. It jerked the wagons and dragged laboriously, And it spins, it spins wheel after wheel, And the gear accelerates, and it goes faster and faster, And it rumbles, and knocks, rumbles and rushes .... I personally sat at the helm of a borrowed tugboat with a flatbed and brought kennel on Modlińska. How cool. After unloading, she stood among the elders from 1938 and 1951. Needless to say, she was in good hands. Here it will be sandblasted and prepared for sheet metal work. Sławek is also coming to consultations tomorrow. I went to do my job, and here the car started whirring around. First, the old soundproofing had to be removed. Why waste time sandblasting them. In addition, an attempt to sandblast flexible elements ends in a fiasco, an increase in temperature and corrugation of the sheet. We don't want that here. The car is supposed to be professionally made and that's how it should be. As you can see, the soundproofing goes down easily and pleasantly. After two hours the floor was exposed. And here's a big surprise. It's not terrible - it's actually good. Of course, the sand will tell the truth, but the original, green primer paint will not turn into holes. Especially since everything looks similar from the other side. There is a lot of putty on the rear fenders, but that's what I expected. It is also worth tapping it before sandblasting. Sanding the putty makes no sense and another unnecessary increase in the temperature of the sheet metal. Around 5 pm, work on the bottom of the kennel began. Tomorrow the continuation, another report.04 Apr 2009 (photo 37)

Another promised dose of photos. From the bottom, after scraping, the original varnish is visible in many places. It all looks nice and promising. Inserts and previous repairs were done ineptly, but everything can be repaired. Today's council of the council of elders unanimously stated - it's good. When I showed Mr. Piotr photos of my friend BJ-ota from Legionowo, he said that mine is a new piece of art. There is a worn putty on the front panel. You can see in one place a small patch made by the previous owner. The side is even so it is not very clear why this putty in such an amount. I guess some standard had to be met. Somebody was conserving something a few years ago. The places covered with red anti-corrosion paint are clearly visible. Oddly enough, there is no rust under it. Mr. Sylwester in action. Below are the first results. Continuation on Monday, and on Tuesday priming sandblasted surfaces. But it's happening.05 Apr 2009

I took apart a piece of the old engine from the blue one. After washing, the elements are like new, including the screws. Without straining too much. I'm installing the oil cooler and filter base tomorrow. All that's left to do is scrape off the old gaskets (I've already done that partly) and screw them on. Maybe, when time permits, I'll bolt the crankshaft on.06 Apr 2009 (photo 38)

Casu little kruca bomb during the day - oh little. Monday is not the best day of the week. I was able to visit a friendly workshop behind the shop for a while and install an oil cooler in the engine. First, some scraping and cleaning of the old seals, then a nice assembly using new seals and o-rings. First, I screwed the radiator to the plaster, and then the whole thing to the engine block. Buda is blushing. Subsequent layers of varnish and unnecessary putty disappear first using a pneumatic sander, and then they are sandblasted. After sandblasting, you can see how the bodywork was done by the predecessors. We will correct all this. A large part of the elements in the front part of the vehicle was thoughtlessly covered with spray putty. Now we just have a lot of unnecessary work. Tomorrow, at the end of the day, I will apply any corrections and the body will be protected with an anti-corrosion primer.07 Apr 2009 (photo 39)

But the work drags on. Despite the pressing, there is a lot of scraping of seals, rubber and various types of particles that reflect the sand. Tomorrow the final inspection and varnishing with primer. As a result of nerves, I ordered two front plates in the states. It will be cheaper to import them than to pick inserts, i.e. corrections after predecessors.08 Apr 2009 (photo 40)

Mr. Józef and Mr. Sylwester sand and starch, starch and sand. Every few hours I drop by and together we find places to clean. They have to be scraped by hand and then sanded. This applies to various edges and sheet joints. Rust can also collect under the rubber. Here you can see very well how the corrosion was hidden under the rubber connecting the wheel arches. After such scraping, the place will be sandblasted again.10 Apr 2009

Bud painted with epoxy primer. I'm taking her to body work on Tuesday. I hope we can make the plate in two bellows. I'm going to take the frame apart next week. Purpose - sandblasting and necessary repairs. We will be doing this on our own. Inserting damaged surfaces is no different from making bumpers or sills - and we can do it10 Apr 2009 (photo 41)

As I wrote earlier, the epoxy paint is already applied. A series of photos of bodywork repairs will be started soon. The inner wheel arches are made of galvanized sheet metal. This sheet is specially selected for repair kits, i.e. it can be properly shaped and does not spring back. The rear fenders and the front left door repair cover are made of the same sheet. Until I find the originals, the blue door will be repaired. Everything waits until Tuesday. Another gasket, another four screws, another element screwed from the puzzle. Someday we'll be able to put it all back together. At least I hope so11 Apr 2009 (photo 42)

Christmas is Christmas and you have to do something. I started the day by tasting the mazurka, and then picking. First, the shaft and shaft supports went to the washer. Then blow with compressed air and you're done. It should be remembered that the supports must be arranged in a strictly defined order. In the 3B engine, you can forget about marking because their numbering and an arrow pointing to the front of the engine are cast on top. Such a simple convenience. Later Toyota engines did not necessarily have arrows. Before we put the shaft in its place, it is worth thoroughly smearing the bearing shells and the shaft with oil so that its first rotations did not take place dry. I immediately prepared the rear crankshaft seal and its bed. Insert the sealant gently so as not to damage it. It should enter evenly from all sides. Before inserting it onto the shaft, it is also worth lubricating it to improve work in the first phase of starting the newly assembled engine. Everything is ready here. Shaft in place and supports with sealant as well. Bolts tightened to the correct torque using a torque wrench. Screw in alternately, evenly distributing the stress on the block. At the end of the Christmas activities, I installed oil washer nozzles. Pressurized oil sprays onto the piston crown. Installing them requires a small patent, but it worked. New o-rings installed, of course.12 Apr 2009 (photo 43)

And waiting gearbox and reducer repair kits. Straight from Australia from the manufacturer The top photo shows the gutters for the reducer and the bottom one for the gearbox.12 Apr 2009

Contrary to what it looks like, I am far from even the new Hilaale Yaris. As a guest from the industry, it is much easier and cheaper for me than Kowalski would do. Many people help me selflessly - for which I am very grateful.14 Apr 2009

Body work has started Buda delivered. I'm delivering the sheets tomorrow.22 Apr 2009 (photo 44)

The purchase of sheet metal has finally come to an end. The last purchase should reach me within 5 working days:wink:. They are replacements but apparently very good quality made like the original. Looking at the pictures, there are actually even the smallest details. On Friday I will try to put the engine back together. Time is scarce as hell for pleasure, but you have to push on. I know that work is going on at the kennel, but as I mentioned, there is no time for visiting.24 Apr 2009

I often watch ebay and stuff like that. I managed to win auctions with a whole new complete exhaust for my car. The Walker company has already finished production of the main muffler. Bosal is not available. Individual elements are available in the original for a lot of money. In a few days, a complete, original exhaust should arrive at half the price of the can itself. I called Slawek yesterday. The kennel has been replaced with beams in the back of the floor and the floor is being repaired.27 Apr 2009

I'm in shock. The sheets arrived in three days from the USA Alexandra wrote that she had sent on the 24th and this morning the package was waiting for me at work. Konus and I drove to the pump maker from Ołtarzew today. Unfortunately, it turned out that row pumps do not touch, but he recommended his friend from Babice. When I give it back, I will show you my conclusions.09 May 2009

I went today after a long break to tinker with the engine. For almost three hours I cleaned the pistons very thoroughly, and then the connecting rods. As I had the piston pin bushings replaced, everything was lying in a cardboard box almost a month after receiving it from the magicians on Parowcowa Street. I wanted to put everything back together, and here's a big linden tree. Piston pin protection is missing. I have injectors from another car in the box, I thought - no problem. You can probably buy it at Toyota and it will cost about two zlotys apiece. And another lime - they were withdrawn from production. On Monday, I'm going to the guests, but they rather kicked out if something happened to them after the workshop. Secondly, they had to give parts to someone without the mentioned injectors. I have a problem because these protections are currently available only with whole pistons for PLN 1100 each. Australia remains, or the demolition of one of the engines. It's a pity because it will take a lot of time. Conclusion: You have to check what you pick up if you have to go to the corner for some time. I will try to mobilize in the coming week and tinker with the car more. I will also take photos of the sheet metal worker going forward.May 13, 2009 (photo 45)