How to control heating to make it more efficient?

Even with an inexpensive source of heat, we will not be satisfied if its daily operation is too burdensome. Meanwhile, control is probably the most often underestimated element of the heating system. And it affects both the comfort of living in the house and the heating costs. Its type must be adapted to the building, heat source, but also to your own habits and preferences.

Controlling gas boilers

Gas boilers are actually maintenance-free devices. Of course, they need service inspections, but the user's action may be limited to selecting the desired temperature in the house. Gas boilers can turn on and off automatically. In addition, modern models have smoothly adjustable power, starting from only a dozen or so percent. It should be noted that they work with very high efficiency in the entire range. Besides, the temperature of the water in the circuit is not of key importance for the efficiency of the boiler.

As a result, these boilers are able to cover the demand for heat on an ongoing basis, all the time with very good combustion efficiency. So there is no need to create accumulation heating, work in different tariffs (we pay the same for gas 24 hours a day), external conditions also do not affect the quality of the boiler's operation. In this case, the method of controlling the heating is adjusted not to the requirements of the boiler itself, but to whether it supplies radiators or surface heating.

It needs to be clarified right away that low-temperature surface heating actually allows condensing boilers to achieve higher efficiency. The difference is a few percentage points. However, there is also the other side of the coin. Radiators can operate in a much more dynamic way than underfloor heating, adapting to changing heat demand. This gives greater control possibilities and can translate into savings in bills - also at least a few percent.

It goes without saying that both variants assume that the controls are selected and configured correctly. And the requirements of radiators and underfloor heating differ significantly. Therefore, we have two basic types of heating automation.

Heating installations using gas are basically maintenance-free, and their control is very convenient. (photo Junkers (Bosch))Room and weather control

Room control is based on a simple and intuitively understandable principle. The operation of the boiler depends on the indications of the temperature sensor placed inside the heated building. In the simplest variant, the boiler turns on when the temperature in the room with the sensor drops below the set value, and stops heating when it is reached. At a slightly more advanced stage, the boiler also automatically changes the temperature of the prepared water, because modern devices work more economically in this way.

It is of great importance to choose the measurement site so that it is representative. Many people choose to put the sensor in the living room, but this is not a good location. The living room often has large windows, which are a source of significant heat gains on sunny days, and if there is a fireplace in it, the lighting completely falsifies the indications.

If the temperature sensor is permanently installed, it should be placed in the coolest room, where there are no large windows or heat sources. These conditions are usually met quite well by the hall. However, it is best to buy a wireless temperature sensor. We can then experimentally choose the best place for it, and move it if necessary. Room automation works very well in cooperation with radiators, because their reaction to the signal from the sensor is almost immediate.

An additional element supervising the operation of radiators, this time individually, are thermostatic heads on their valves. Alternatively, they can be more advanced electronic heads whose settings can be programmed and even changed remotely. It's much more convenient than going around the whole house for this purpose.

Radiators enable quick heating of the room. (photo Regulus-System)So we have a two-stage system - first the boiler is controlled by a temperature sensor (on/off, change of water temperature), then the correction is made thanks to the heads on the radiator valves in individual rooms. Such a system, however, does not cope well when the heating has a large inertia - it takes a long time to react to a change in heat demand. The flagship example here is typical underfloor heating.

Weather automation makes the operation of the boiler or other heat source dependent on the signals from the temperature sensor located outside the house, not inside. Where did this idea come from? Why not measure the temperature inside?

First of all, because the inside temperature ultimately depends on the outside temperature. If it gets colder outside, the heat loss of the building increases, because more of it escapes through the external partitions and ventilation. This, in turn, results in a decrease in the temperature in the rooms, if we do not start heating more intensively. The problem is that it is not easy to precisely determine this correlation. It depends on the characteristics of the building itself and its heating system.

If it is well insulated and massive (heavy), which is true of almost any brick house, it will heat up and cool down slowly. All the more so if its heating is a typical floor heating system, i.e. pipes in a screed that is about 7 cm thick. Such a heavy (approx. 150 kg/m2) floor needs a lot of time to react, especially since it is supplied with water at a fairly low temperature (30-55°C). If you wait with its activation until the temperature in the rooms drops, it will take a long time before it reaches the set level again, and we will freeze.

And that's where weather automation comes in. It takes into account the decrease or increase of the external temperature, turning the heating on and off in advance and changing the temperature of the water in the circuit. Thanks to this, it eliminates the inertia in the heating operation.

Weather regulators set the desired temperature of the heating water, taking into account the actual temperature outside the building. Thanks to this, they react to cooling or warming up before cooling down or overheating the rooms. (photo by Vaillant)Works in accordance with the so-called heating curve, showing the relationship between the external temperature and the temperature of the water in the circuit (the colder it is, the hotter it must be), and at what temperature the central heating it needs to run at all. Matching the right curve to a specific building is not easy and often requires adjustment. This is done either manually or automatically. More and more often there are also systems in which there is both an external and internal sensor. Thanks to this, the correctness of the heating curve setting is corrected on an ongoing basis.

Heating curves illustrate the relationship between the outside temperature and the temperature of the water in the circuit. Which curve will be good depends on the characteristics of a particular house.It should be added that some of the boilers are so-called. two-circuit devices. This means that they can supply a heating installation divided into two parts with different characteristics, each with its own control. This is the best solution if we have both radiators and underfloor heating.

It should be remembered that the interiors of typical brick houses equipped with underfloor heating take a long time to heat up and cool down. (photo by Tece)Controlling a coal or pellet boiler

The convenience of using a solid fuel boiler depends on which device we choose. It can be said that the level of technical advancement translates into the price. The simplest charging boilers, without a feeder and automation, can be bought for PLN 2,000-3,000. However, you have to light them every day and refuel several times a day. And the possibilities of changing the power, and thus adapting to the instantaneous demand for heat, are very limited.

Models with a feeder can cost up to several thousand zlotys. However, they are refueled once every few days, so service is very limited. In addition, they can have very advanced automation - with room and weather sensors, and remote control via the Internet. Also, the power supply of two heating circuits, each with its own automation, is available in them.

There are also more and more models with the function of automatic ignition and extinguishing. Most of them are in the case of pellet boilers, because this fuel is easier to ignite, and it is more difficult to keep the embers on it than in the case of coal. However, this solution is also becoming popular in coal-fired boilers. It should be noted right away that the automatic firing-up gives the possibility of eliminating the work in the ember sustaining mode in periods of low heat demand, especially in the summer, when only domestic hot water is needed. Then, maintaining the embers not only consumes even more fuel than just preparing the water, but above all it means combustion with low efficiency and high emission of pollutants.

Contemporary modern solid fuel boilers can easily work with any type of heating, both with radiators and underfloor heating. The latter requires only a suitable mixing system so that the temperature of the boiler itself is sufficiently high.

Modern solid fuel boilers can also be controlled via the Internet. (photo Galmet)What distinguishes solid fuel boilers from gas devices is a clear decrease in efficiency when they work with a lower than nominal power. However, it is worth knowing that they can operate with a power slightly exceeding the nominal (up to 20%), almost without losing efficiency. Therefore, it is necessary to strongly advise against the common practice of buying boilers with a higher power than actually needed, i.e. the so-called oversizing.

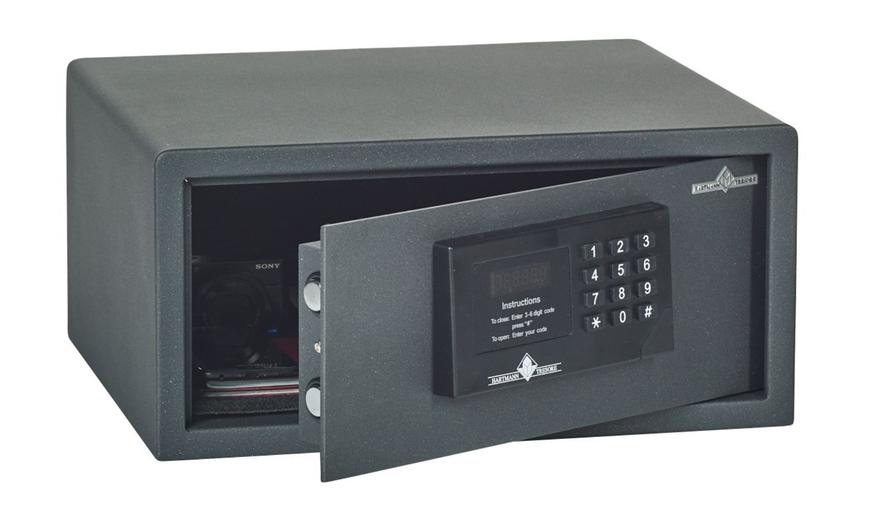

A specific case where it is acceptable is the powering of the accumulation tank. It is a large-capacity tank, usually 500-1000 l, for heating water. The boiler heats it up to 90°C, while operating at nominal power and maximum efficiency. Even if it expires later, we have a reserve of heat stored in the water for later. This is a very good solution for boilers burning wood in logs and fireplaces with a water jacket - wood feeding cannot be automated.

Charge-fired coal boilers also work well with the storage tank. In this case, it is advisable to use automatic control not of the boiler itself, but of the central heating circulation pump. between the tank and the radiators and the underfloor heating. Its activation causes gradual discharge of heat from the storage tank. At the same time, in a system with an accumulation tank, underfloor heating can be a very good solution. The floor screed is in itself an additional heat accumulator.

In addition, water at a temperature of 30°C is sufficient for its effective heating, which means that heat can be drawn from the tank until it cools down to this level, while for radiators a reasonable minimum is approx. 50°C. We will return to the problem of heat accumulation and control of such systems when discussing electric heating, because there are additional factors that must be taken into account.

Electric heating control

Electric heating is actually many different systems. First of all, they are associated with the so-called direct heating, i.e. radiators or electric underfloor heating (mats, wires, heating foils). However, we still have electric boilers that operate fully maintenance-free and constantly with the highest efficiency. They are often used together with solid fuel boilers. Heat from coal or wood is cheap, and the electric boiler can work fully automatically. Then, for example, a few-day ski trip in the heating season is no longer a problem.

There is also an electric accumulation heating in the form of the so-called storage heaters and heat pumps, which also need electricity to operate. The choice of the type of heating is of key importance here, because the investment and operating costs can be completely different. At the same time, each variant requires a completely different configuration of the heating system and its control. Various solutions for heat accumulation are of particular importance here, because thanks to them you can use dual-tariff billing for electricity (cheap electricity at night).

Owning a photovoltaic installation can also be an important factor. Own electricity from solar cells can completely change the economic calculation. And at the same time, the current legal regulations allow to transfer excess electricity to the grid, and then collect it even with a delay of several months. Thanks to this, the basic problem of any form of installation using the sun, which, after all, provides us with the least energy in the winter season, is solved.

The least complicated form of electric heating is radiators in individual rooms, each with its own thermostat. We do not actually build any special heating installation here. Such a system is very cheap in terms of investment (heaters can be bought even for less than PLN 200 per unit) and, contrary to appearances, comfortable, especially if the heaters are equipped with timers, even the simplest ones, plugged into the socket. And without any complicated automation.

However, this solution has never been popular and probably will not be, due to high electricity prices in the basic tariff (approx. PLN 0.60 / kWh). Although it must be admitted that this method of heating may make sense in the case of houses with extremely low heat demand, similar to the passive standard. It is also justified in buildings heated occasionally (a house on a plot), or as a maintenance-free supplement to another heating method (charging boiler, fireplace). Similarly, electric heating in bathrooms should also be treated as a supplementary element, and not a full-fledged heating, the purpose of which is only to provide a floor that is warm to the touch.

Two types of cables are used in electric floor heating - constant resistance and self-regulating. The former always heat at full power. Self-regulating cables heat the more, the lower the temperature in the vicinity of the cable. (photo by Elektra)Electric storage heating in the form of the so-called accumulation stoves or underfloor heating with a thick layer of screed. In this case, we strive to use a cheaper tariff with the so-called dual-zone heating. Then we have cheap electricity at night (22.00-6.00) and shortly during the day (e.g. 13.00-15.00), but more expensive than with single-zone billing for the rest of the day. Some energy providers also offer a cheap tariff throughout the weekend. The assumption is that during the lower rate hours we store enough heat to last around the clock. So the basis is time control.

A simpler, less comfortable version is the accumulation stoves with the so-called static discharge and a floor with heating cables in a thick screed. Here we heat up a certain accumulation mass, which then gives off the heat. With the proviso that we no longer have control over this phase of heat dissipation, it is done automatically. More possibilities are offered by furnaces with the so-called dynamic discharge. In them we usually have fans that intensify or stop the movement of air, and with it the heat dissipation. The possibilities of controlling the device itself, and therefore control over the temperature in the room, become much better. With the correct configuration, such a system is not inferior in terms of comfort to typical heating with wall radiators.

For those who use electricity for heating purposes, photovoltaic installations are particularly attractive. In our climate, 1 kW of installed power of such a small power plant gives about 1000 kWh of energy per year. With the proviso that its production is very uneven, with the predominance of spring and summer several times over the winter months. Unfortunately, it is in winter that we need the most energy.

Fortunately, current legal regulations oblige energy suppliers to accept excess energy from us, in exchange for which we can collect 80% of it even after a few months, when we need it. It should be emphasized here that the rules, especially the length of the period in which this balance sheet settlement is made, may be different. Ideally, they should be as long as possible, e.g. half a year, and any surplus from one period would be transferred to the next. Therefore, if we have a photovoltaic installation, check the terms of the contract with our energy supplier especially carefully.

Heat pumps are a special case, especially the so-called hybrid devices, i.e. a gas boiler and an air heat pump combined in one heating center. Similarly, the so-called bivalent installations, where we have a heat pump and some traditional heating device, providing heat when the operation of the pump becomes insufficient or unprofitable. Hybrid devices are interesting because there we immediately get refined automation, deciding which of the heating devices should work at a given moment. So as to ensure the desired temperature in the interiors, and at the same time the operating costs were as low as possible - taking into account the efficiency in given conditions and the price of energy (gas / electricity). Here again, an additional variable is introduced by photovoltaic panels, thanks to which electricity ultimately becomes cheaper.

Besides, the automation is typical, i.e. room or weather. The latter is more popular in the case of heat pumps, because floor heating dominates in these systems. In principle, the only specific modification of the control method in the case of heat pumps should be the pursuit of maintaining the lowest possible temperature of the water in the circuit, because then the pump works more economically.

For the heat pump to work more economically, the circulating water should be as cold as possible. (photo by Nibe Biawar)What is a reasonable return on investment in home heating? Construction manager advises...

BDN editorsIn the opening photo: Junkers (Bosch), Immergas